DSC Global - INSPECTION OF OIL & GAS PIPELINE

DSC Global is one of the leading in-line inspection companies in the World. For many years it has been developing electromagnetic & ultra-sonic in-line inspection technologies, providing safe operation of gas & oil pipe-lines. It develops electromagnetic and ultrasonic in-line inspection technologies, designs and produces high resolution in-line inspection tools and cleaning pigs, renders in-line inspection services, including ILI data treatment, using original software, prepares ILI reports.

DSC Global has a powerful scientific research & production base with computer ILI data treatment center. DSC Global ILI tools are equipped with electronically controlled built-in bypasses aimed to create good recording speed of ILI tool run in gas flow up to 18 m/second. Every year DSC Global ILI tools inspect thou-sands kilometers of trunk pipelines.

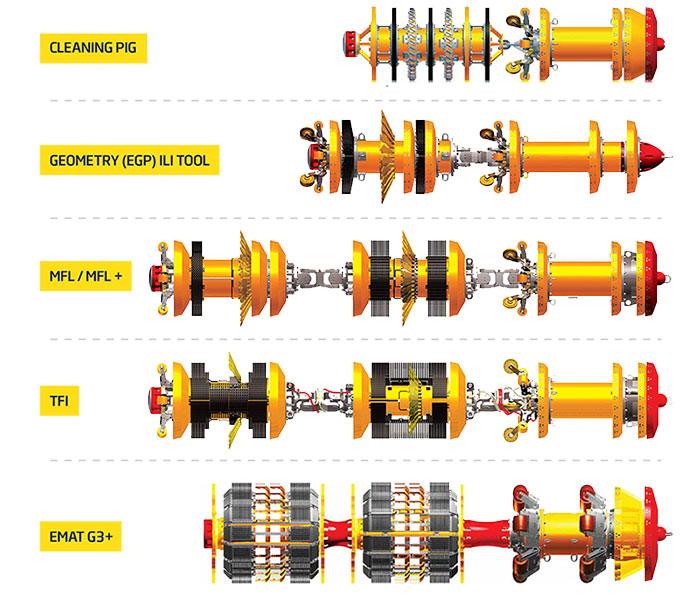

DSC Global sets of ILI tools diameter from 10" to 56" are destined for cleaning pigging and high resolution in-line inspection of trunk gas, oil, oil product pipelines on land and offshore. High resolution in-line inspection tools include electronic geometry tools with XYZ mapping, magnetic flux leakage (MFL) HR ILI tools, introscopes (MFL+) for detection of pipeline defects on inner pipe wall surface, transverse flux inspection (TFI) HR ILI tools, electromagnetic acoustic (EMAT) ILI tools for detection and identification of tiny stress corrosion cracks as well as disbonded coating pipe zones.

INTERNATIONAL IN-LINE INSPECTION OPERATIONS

DSC Global has been successfully inspecting trunk pipe-lines of gas and oil companies in Argentina, Mexico, Lithuania, Latvia, Estonia, Finland, Poland, Germany, Ukraine, Kazakhstan, Uzbekistan, Byelorussia, the Czech Republic, UAE, Iran, India. DSC Global has highly professional English-speaking certified field teams for work abroad. International certificates are available for ILI tools.

For foreign customers ILI reports are issued in English, including original software, according to ASME B31 G, DNV RP F 101, BS 7910.2005 and other interna-tional standards. Final reports correspond to “DSC Global & Requirements for Intelligent Pig Inspection of Pipelines” Shell Exploration & Production B.V. Version 3.2. 2005. Representatives of foreign companies are trained to use the data of ILI reports for efficient pipe-line repair.

- COMPLETE SET OF IN-LINE INSPECTION TOOLS

- DIAMETERS OF ILI TOOLS

- EMAT IN-LINE INSPECTION TECHNOLOGIES

- DETECTED DEFECT TYPES

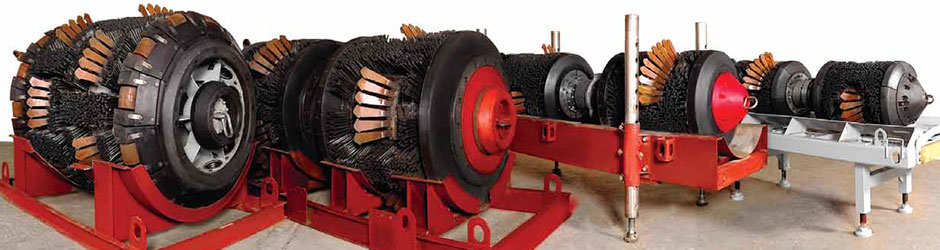

COMPLETE SET OF IN-LINE INSPECTION TOOLS

- Available diameters of ILI tools: 10”-56”

- Maximum gas flow ed 18 m/s

- Minimum passable curvature ID radius: EGP - 1.5 DN; MFL/ TFI/ EMAT - 2.5 DN

- Maximum pressure: 12 MPA

- Transported products: dry sweet gas, LPG, crude oil, oil products, water, etc.

- Maximum length of a pipeline section per run: 1250 km

- Product temperature in a pipeline: up to +50° C

SPECIFICATIONS OF ILI TOOLS

DIAMETERS OF ILI TOOLS 10” – 56”

BUILT-IN ELECTRONICALLY CONTROLLED BYPASSES

Three different types of electronically controlled built-in bypasses were developed in “DSC Global” to maintain good recordable speed of an in-line inspection tool run (optimum speed is not higher than 2.5 m/sec.) in a pipeline with gas flow speed up to 18 m/sec. Nearly all types of ILI tools are equipped with bypasses

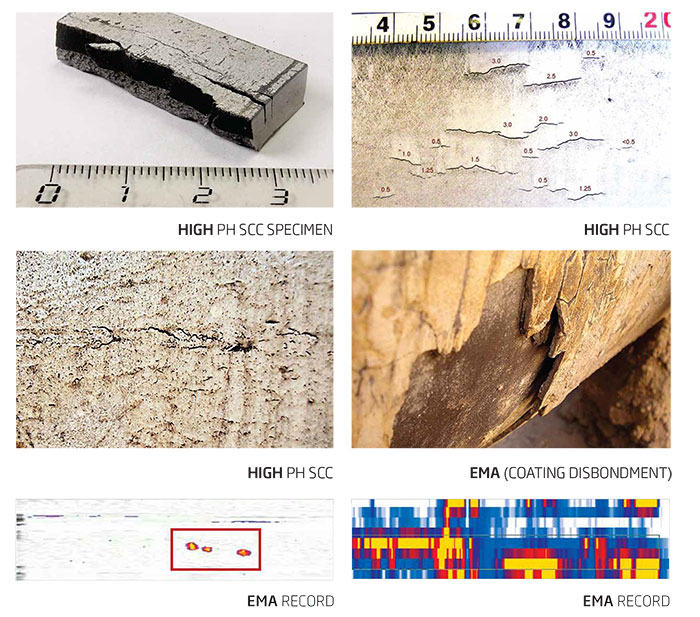

EMAT IN-LINE INSPECTION TECHNOLOGIES

DSC Global has been developing in-line inspection tools for detecting, identifying and sizing shallow narrow zones of cracks of high PH origin. The target is SCC zone with maximum depth of individual cracks less than 10% pipe wall thickness with nearly zero opening (>10 µm). Several generations of EMA tools were developed and run in gas pipelines. Several thousand kilometres of gas pipelines were inspected by EMAT ILI tools. Multiple stress corrosion cracks were detected, identified and located by EMAT ILI tools, being confirmed by pipeline digging excavations.

DSC Global EMAT tools are the first dry electromagnetic - ultrasonic ILI tools, able to detect and identify high PH cracks in gas pipelines without liquid inside them. Another application of EMAT ILI tools is detection of disbonded coating zones in pipelines as potentially dangerous ones for future defects origina-tion , also helping to check up efficiency of pipeline cathodic protection.

DIAMETERS OF AVAILABLE EMAT ILI TOOLS: 24”.30”,40”,42”,56”

More than 800 channels for crack detection, coating disbondment detection, pipe thickness measurement, data record quality control

EMAT RESULTS

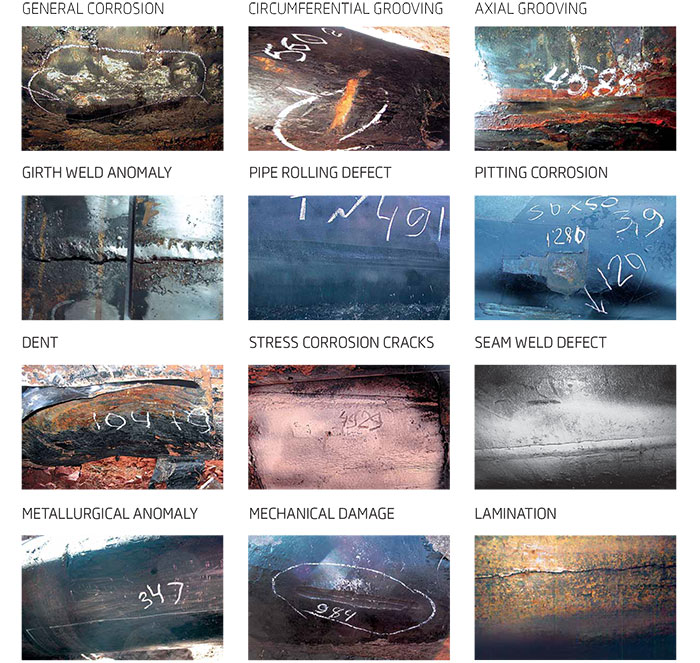

DETECTED DEFECT TYPES