About Plug Valves

The simplest and most common general type of plug valve is a 2-port valve, which has two positions, opens to allow flow, and shut (closed) to stop flow. Ports are openings in the valve body through which fluid can enter or leave.

The plug in this kind of valve has one passageway going through it. The ports are typically at opposite ends of the body; therefore, the plug is rotated a fourth of a full turn to change from open to shut positions. This makes this kind of plug valve a quarter-turn valve. There is often a mechanism limiting motion of the handle to a quarter turn, but not in glass stopcocks.

Slightly conically-tapered metal (often brass) plug valves are often used as simple shut-off valves in household natural gas lines.

It is also possible for a plug valve to have more than two ports. In a 3-way plug valve, flow from one port could be directed to either the second or third port. A 3-way plug valve could also be designed to shift flow between ports 1 and 2, 2 and 3, or 1 and 3, and possibly even connect all three ports together. The flow-directing possibilities in multi-port plug valves are similar to the possibilities in corresponding multi-port ball valves or corresponding multi-port valves with a rotor. An additional possibility in plug valves is the have one port on one side of the plug valve and two ports on the other side, with two diagonal and parallel fluid pathways inside the plug. In this case the plug can be rotated 180° to connect the port on the one side to either of the two ports on the other side.

Stopcocks used in laboratory glassware are typically forms of conically-tapered plug valves. When fused with the glassware, the valve bodies are made of glass. Otherwise, they can be made of an inert plastic such as Teflon. The plugs can be made of a similar plastic or glass. When the plug is made of glass, the handle and plug are fused together in one piece out of glass. When glass is used for both the stopcock body and the plug, the contacting surfaces between them are special ground glass surfaces (see Laboratory glassware) often with stopcock grease in between. Special glass stopcocks are made for vacuum applications, such as in use with vacuum manifolds. Stopcock grease is always used in high vacuum applications to make the stopcock air-tight.

Butterfly Valves Product List

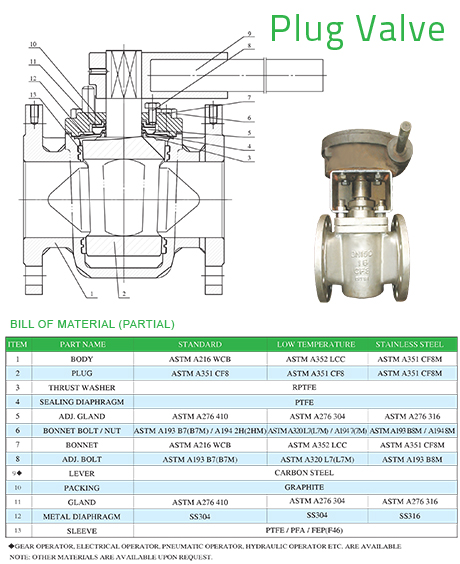

- Lubricated Plug Valve With Bottom-Entry

-

Product Details Lubricated Plug Valve With Bottom-Entry Design and Manufactur ASME B16.34, API 6D, API 599, API 6A Face to Face Dimension ASME B16.10, API 6A Flange Connection Dimension ASME B16.5, API 6A BW Connection Dimension ASME B16.25 Threaded Ends Dimension ASME B1.20.1 Socket Welded Ends Dimension ASME B16.11 Pressure-Temperature Ratings ASME B16.34 Test and Inspection API 598, API 6D, API 6A Type of Operation Manual, Gear, Electric, Pneumatic NPS 1/2"~16" Class 900lb~1500lb Main Material WCB, WCC, WC6, WC9, LCB, LCC, C5, C12, CF8, CF8M, CF3, CF3M, CF8C, CN7M, A105, LF2, F5, F9, F11, F22, F304, F304L, F316, F316L, F321 - Non-Lubricated Plug Valve

-

Product Details Non-Lubricated Plug Valve Design and Manufactur ASME B16.34, API 6D, API 599, API 6A Face to Face Dimension ASME B16.10, API 6A Flange Connection Dimension ASME B16.5, API 6A BW Connection Dimension ASME B16.25 Threaded Ends Dimension ASME B1.20.1 Socket Welded Ends Dimension ASME B16.11 Pressure-Temperature Ratings ASME B16.34 Test and Inspection API 598, API 6D, API 6A Type of Operation Manual, Gear, Electric, Pneumatic NPS 1/2"~16" Class 150lb~600lb Main Material WCB, WCC, LCB, CF8, CF8M, CF3, CF3M, CF8C, CN7M, A105, F304, F304L, F316, F316L, F321 - Plug Valve With Single Flush

-

Product Details Plug Valve With Single Flush Design and Manufactur ASME B16.34, API 6D, API 599 Face to Face Dimension ASME B16.10 Flange Connection Dimension ASME B16.5 BW Connection Dimension ASME B16.25 Threaded Ends Dimension ASME B1.20.1 Socket Welded Ends Dimension ASME B16.11 Pressure-Temperature Ratings ASME B16.34 Test and Inspection API 598, API 6D Type of Operation Manual, Gear, Electric, Pneumatic NPS 1/2"~16" Class 150lb~600lb Main Material WCB, WCC, LCB, CF8, CF8M, CF3, CF3M, CF8C, CN7M, A105, F304, F304L, F316, F316L, F321

Certificate of Warranty

GOC warrant that all the valves are new, unused, and all the materials conform to the ASTM/ASME standard and all the valves have been tested as per API 598 or API 6D. We further warrant that all valves supplied have no defects arising from design, materials. This warranty will remain for twelve (12) months after the date of shipment from the port of loading.